TRAGEDY AND RECOVERY 1967

Nestled beside an umbilical tower, surrounded by a service structure, and encased in a clean room at Cape Kennedy’s Launch Complex 34, spacecraft 012 sat atop a Saturn IB on Friday morning, 27 January 1967. Everything was ready for a launch simulation, a vital step in determining whether the spacecraft would be ready to fly the following month. During this “plugs out” test, all electrical, environmental, and ground checkout cables would be disconnected to verify that the spacecraft and launch vehicle could function on internal power alone after the umbilical lines dropped out.

By 8:00 that morning, a thousand men, to support three spacesuited astronauts–Virgil Grissom, Edward White, and Roger Chaffee–were checking systems to make sure that everything was in order before pulling the plugs. In the blockhouse, the clean room, the service structure, the swing arm of the umbilical

tower, and the Manned Spacecraft Operations Building, this army of technicians was to go through all the steps necessary to prove that this Block I command module was ready to sustain three men in earth-orbital flight. Twenty-five technicians were working on level A-8 of the service structure next to the command

module and five more. mostly North American employees, were busy inside the clean room at the end of the swing arm. Squads of men gathered at other places oil the service structure. If interruptions and delays stretched out the test, as often happened, round-the-clock shifts were ready to carry the exercise to a conclusion. Throughout the morning, however, most of the preparations went smoothly, with one group after another finishing checklists and reporting readiness.

After an early lunch, Grissom, White, and Chaffee suited up, rode to the pad (arriving an hour after noon), and slid into the spacecraft couches. Technicians sealed the pressure vessel inner hatch, secured the outer crew access hatch, and then locked the booster cover cap in place. All three astronauts were instrumented with biomedical sensors, tied together on the communications circuit, and attached to the environmental control system. Strapped down, as though waiting for launch, they began purging their space suits and the cabin atmosphere of all gases except oxygen–a standing operating procedure. (2)

STALKED BY THE SPECTRE

For almost a year, the Grissom crew had watched its craft go through the production line, test program, and launch pad preparations. After participating in a multitude of critiques, reading numerous discrepancy reports, and going through several suited trials in the spacecraft in altitude chambers at Downey and the Cape, Grissom’s group had learned almost all the idio- syncracies of spacecraft 012. The astronauts knew, if not every nut and bolt, at least the functions of its 88 subsystems and the proper positions for hundreds of switches and controls inside the cockpit. They also knew that the environmental unit had been causing trouble. Indeed, Grissom’s first reports on entering the cabin were of a peculiar odor–like sour milk.

As all traces of sea-level atmosphere were removed from the suit circuit and spacecraft cabin, pure oxygen at a pressure of 11.5 newtons per square centimeter (16.7 pounds per square inch) was substituted. The crew checked lists, listened to the countdown, and complained about communications problems’ that caused intermittent delays. The men could speak over four channels, either by radio or telephone line, but the tie-in with the test conductors and the monitors was complicated and troublesome. Somewhere there was an unattended live microphone that could not be tracked down and turned off. Other systems, Grissom’s crew noted, seemed to be operating normally. At four in the afternoon, one shift of technicians departed and another came on duty.

Near sunset, early on this winter evening, communications problems again caused a delay, this time for ten minutes, before the plugs could be pulled. Thus, the test that should have been finished had not really started, and an emergency egress practice was still to come. The crew was accustomed to waiting, however, having spent similar long hours in trouble-plagued training simulators. About 6:30, Grissom may have been thinking about the jest he had played on Riley McCafferty by hanging a lemon on the trainer.

Donald Slayton sat half a kilometer away at a console in the blockhouse next to Stuart Roosa, the capsule communicator. On the first floor of the launch complex Gary W. Propst, an RCA employee, watched a television monitor that had its transmitting camera trained on the window of the command module. Clarence A. Chauvin, the Kennedy Space Center test conductor, waited in the automated checkout equipment room of the operations building, and Darrell O. Cain, the North American test conductor, sat next door. NASA quality control inspector Henry H. Rogers boarded the Pad 34 elevator to ride up to the clean room. There, at the moment, were three North American employees: Donald O. Babbitt, pad leader; James D. Gleaves, mechanical technician; and L. D. Reece, systems technician. Reece was waiting to pull the plugs on signal. Just outside on the swing arm, Steven B. Clemmons and Jerry W. Hawkins were listening for Reece to call them to come and help. All of these men and several others in the vicinity at 6:31 heard a cry over the radio circuit from inside the capsule: “There is a fire in here.

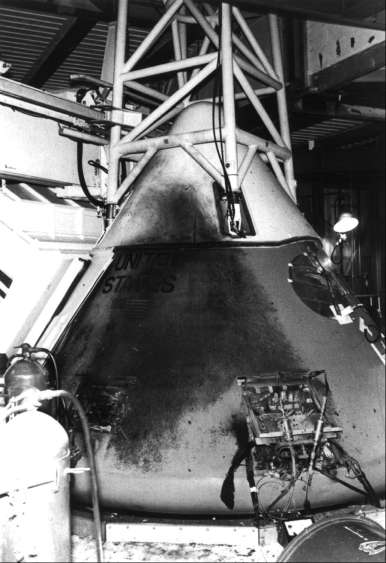

Stunned, pad leader Babbitt looked up from his desk and shouted to Gleaves: “Get them out of there!” As Babbitt spun to reach a squawk box to notify the blockhouse, a sheet of flame flashed from the spacecraft. Then he was hurled toward the door by a concussion. In an instant of terror, Babbitt, Gleaves, Reece, and Clemmons fled. In seconds they rushed back, and Reece and Clemmons searched the area for gas masks and for fire extinguishers to fight little patches of flame. All four men, choking and gasping in dense smoke, ran in and out of the enclosure, attempting to remove the spacecraft’s hatches.

Meanwhile, Propst’s television picture showed a bright glow inside the spacecraft, followed by flames flaring around the window. For about three minutes, he recalled, the flames increased steadily. Before the room housing the spacecraft filled with smoke, Propst watched with horror as silver-clad arms behind the window fumbled for the hatch. “Blow the hatch, why don’t they blow the hatch?” he cried. He did not know until later that the hatch could not be opened explosively.” Elsewhere, Slayton and Roosa watched a television monitor, aghast, as smoke and fire billowed up. Roosa tried and tried to break the communications barrier with the spacecraft, and Slayton shouted furiously for the two physicians in the blockhouse to hurry to the pad.

In the clean room, despite the intense heat, Babbitt, Gleaves, Reese, Hawkins, and Clemmons, now joined by Rogers, continued to fight the flames. From time to time, one or another would have to leave to gasp for air. One by one they removed the booster cover cap and the outer and inner hatches–prying out the last one five and a half minutes after the alarm sounded. By now, several more workers had joined the rescue attempt. At first no one could see the astronauts through the smoke, only feel them. There were no signs of life. By the time firemen arrived five minutes later, the air had cleared enough to disclose the bodies. Chaffee was still strapped in his couch, but Grissom and White were so intertwined below the hatch sill that it was hard to tell which was which. Fourteen minutes after the first outcry of fire, physicians G. Fred Kelly and Alan C. Harter reached the smoldering clean room. The doctors had difficulty removing the bodies because the spacesuits had fused with molten nylon inside the spacecraft.

As anguished officials gathered, the pad was cleared of unnecessary personnel, guards were posted, and official photographers were summoned. All through the night, physicians labored to complete their grim task. After the autopsies were finished, the coroner reported that the deaths were accidental, resulting from asphyxiation caused by inhalation of toxic gases. The crew did have second and third degree burns, but these were not severe enough to have caused the deaths.

Most persons who had been connected with the space program in any way remember that the tragedy caught them by surprise. In six years of operation, 19 Americans had flown in space (7 of them, including Grissom, twice) without serious injury. Procedures and precautions had been designed to foresee and prevent hazards; now it was demoralizing to realize the limits of human foresight. Several other astronauts had died, but none in duties directly associated with space flight. Airplane crashes had claimed the lives of Elliot See, Charles Bassett, and Theodore Freeman. These were traumatic experiences, but the loss of three men during a ground test for the first manned Apollo flight was a more grievous blow.

Memorial services for the AS-204 crewmen were held in Houston 30 January, although their bodies had been flown north from Kennedy for burial. Grissom and Chaffee were buried in Arlington National Cemetery and White at the Military Academy at West Point. Amid these last rites, a similar tragedy took the lives of two men in an oxygen-filled chamber at Brooks Air Force Base in San Antonio. Airman 2/c William F. Bartley and Airman 3/c Richard G. Harmon were drawing blood samples from rabbits when a fire suddenly swept through the enclosure. The spacecraft and chamber tragedies pinpointed the dangers inherent in advanced space-simulation work.

The accident that took the lives of Grissom, White, and Chaffee was heartrending, and some still insist totally unnecessary; but NASA had always feared that, in manned space flight, danger to pilots could increase with each succeeding program. Space flight officials had warned against undue optimism for years, pointing out that any program that large inevitably took its toll of lives–from accident, overwork, or illness brought on by the pressures of such an undertaking. Man was fallible; and a host of editorial cartoons reiterated this axiom for several months after the fire. One, by Paul Conrad in the Los Angeles Times, showed the spectre of death clothed in a spacesuit holding a Mercury spacecraft it one hand, a Gemini in the other, and with the smoldering Apollo in the background. It was captioned “I thought you knew, I’ve been aboard on every flight.”

While preaching the need to promote quality workmanship, NASA managers had relied on their contractors to invoke effective measures. NASA executives knew they had tried to inspire the whole Apollo team to strive for perfection, but the haunting question now was: Had they tried hard enough? Every company and organization had a management scheme to increase personal motivation by giving recognition to faultless performance. North American had its “PRIDE” program, standing for “Personal Responsibility in Daily Effort,” and NASA had “MFA” for “Manned Flight Awareness.” The NASA program also featured what was called the “Lunar Roll of Honor”; the first lunar landing party would carry a microfilm listing 300 000 names, honoring the exceptional service of those who had aided significantly in the achievement. After the fire, the idea was dropped. Just as it became obvious how difficult it was to fix the blame for failure, it would later be come apparent that it would be equally hard to pinpoint responsibility for success.

In Washington on the day of the accident, an Apollo Executives’ Conference was in session, attended by NASA leaders James Webb, Robert Seamans, and George Mueller and by top Gemini and Apollo corporate officials, to mark the transition from two- to three-man space flight operations. That morning the conferees had been invited to the White House to witness the signing of a space treaty. President Johnson described this event as the “first firm step toward keeping outer space free forever from the implements of war.” Later, as the tragic news from Pad 34 spread, the executives considered disbanding. Administrator Webb, however, decided to carry on; Mueller would stay in Washington and Seamans and Samuel Phillips would go to the Cape. The next day, Mueller reported the first few meager facts to the meeting and then gave a paper that Phillips had intended to present.

Ironically, Phillips had listed troubles with quality assurance among the top ten problems faced in Apollo.

THE INVESTIGATION

After the fire, amid all the grief and the shock that it could have happened, a thorough fact-finding investigation was conducted. Webb and Seamans asked Floyd L. Thompson, Director of Langley Research Center, to take charge of the inquiry. Thompson and Seamans met at Kennedy at noon on 28 January for a brief session with other Headquarters, Houston, and Cape officials and then adjourned to Complex 34 to see the scene of the accident.

Seamans returned to Washington that evening, consulted with Webb, and drafted a memorandum formalizing the AS-204 Review Board with Thompson as chairman. Members were astronaut Frank Borman and Max Faget of the Manned Spacecraft Center, E. Barton Geer of Langley Research Center, George W. Jeffs of North American, Franklin A. Long of Cornell University and the President’s Science Advisory Committee, Colonel Charles F. Strang of the Air Force Inspector General’s office, George C. White of NASA Headquarters, and John J. Williams of Kennedy Space Center.

The board quickly established tight security at Complex 34, impounded documents pertaining to the accident, and collected eyewitness reports. News media representatives swarmed in to cover the story, and their unofficial investigations and semifactual innuendos filled newsprint and airwaves throughout the following weeks. Many looked for quick answers and simple explanations, but by 3 February it was obvious to NASA officials, at least, that no single cause for the accident could be isolated immediately. Seamans and Thompson set lap 21 panels to assist the review board. When he realized that full-time participation was expected. Long asked to be excused. He was replaced by Robert W. Van Dolah, an explosives expert from the Bureau of Mines. In other personnel actions, Seamans asked Jeffs to serve as a consultant rather than as a board member and George T. Malley, chief counsel at Langley, to act as legal advisor.

Anticipating public clamor for answers and reforms, if not postponement of Apollo, NASA officials asked leading members of Congress to hold off on a full-scale investigation until the review board finished its report. Senator Clinton P. Anderson. Chairman, agreed to call the Senate Committee on Aeronautical and Space Sciences into executive session only, for its early investigations. And Representative George P. Miller, Chairman of the House Committee on Science and Astronautics, said Olin Teague’s Subcommittee on NASA Oversight would not begin hearings until the Thompson Board had submitted its report. Many newsmen charged that the full story would never be known, since most of the board members were NASA employees; others conjectured that Apollo might be grounded altogether. Meanwhile, the Apollo 204 Review Board went systematically about its business.

Seamans returned to Florida on 2 February to prepare a preliminary report for Webb. Although this was made public just few days later, accusations still swirled that the NASA investigation could not be impartial since it was a probe of the agency by itself. There were also sensationalistic charges such as those in Eric Bergaust’s book, Murder on Pad 34, a year and a half later. Bergaust said that NASA, even while denying that it was in a space race, had nevertheless placed speed above safety.

But there was plenty of evidence that meeting schedules was not the whole story. “We’re in a risky business,” Grissom himself had said in an interview several weeks before the fire, ” and we hope if anything happens to us, it will not delay the program. The conquest of space is worth the risk of life.” He was later quoted as saying, “Our God-given curiosity will force us to go there ourselves because in the final analysis only man can fully evaluate the moon in terms understandable to other men. “

Congressional leaders did not entirely share the views and misgivings of the press. In a bipartisan move, Senators Anderson and Margaret Chase Smith arranged for publication of the executive hearings of 7 February with Seamans, Mueller, Charles A. Berry (Houston’s medical director of manned space flight), and Richard Johnston (spacesuit and life support systems expert). This openness of congressional deliberations helped to defuse media criticism about the objectivity of the ongoing investigation.

Spacecraft 014, nearly identical to 012, was shipped from California to Florida. There the Thompson Board and its panels had the vehicle dismantled for comparison with the remains of 012, which was being taken apart and every piece studied and analyzed. Thompson took advantage of the background and experience of his board members, assigning some to monitor several of the panels. While technicians worked around the clock for the first few weeks, the board held daily recorded and transcribed sessions to consider the findings. Strang was an effective vice-chairman, drawing on his background as an inspector to organize proceedings and prepare comprehensive reports. Van Dolah, the mining explosives expert, had only one panel–origin and propagation of the fire–to monitor, emphasizing the importance of finding that answer. Thompson reserved a single panel, medical analysis, for himself.

Faget had the heaviest load of panels: sequence of events, materials review, special tests, and integration analysis. Borman drew the teams on disassembly, ground emergency provisions, and inflight fire emergency provisions. Williams monitored the spacecraft and ground support equipment configuration, test procedures review, and service module disposition. George White, quality and reliability chief from Headquarters, was responsible for investigations into test environments, design reviews, and historical data. An associate of Thompson’s from Langley, Geer handled the groups on the analysis of spacecraft fractures, the board’s administrative procedures, and the safety of the investigation operations themselves. Strang was left with the panels taking statements from witnesses, handling the security operations of the inquiry, and writing up the final report.

When Seamans made a second preliminary report to Webb, on 14 February, it was clear that the fire was indeed a fire, and not an explosion leading to a fire. Physical evidence indicated that the conflagration had passed through more than one stage of intensity before the oxygen inside the cabin was used up. By mid-February, the work of tearing down the command module had reached a point where a two-shift

six-day week could replace round-the-clock operations.

On the day of the scheduled launch of AS–204, 21 February, the board gave preliminary briefing to George Mueller and a dozen other top NASA officials in preparation for a major briefing of Seamans. Thompson told Seamans the next day that 1500 persons were directly supporting the investigation–600 from government and 900 from industry and the universities–and that the board planned to complete its report by the end of March. Although the history of the fire after it started had been minutely reconstructed, the specific source of ignition had not been–and might never be–determined. On 25 February, Seamans prepared a memorandum for Webb, listing early recommendations by the board that the Administrator could present to Congress:

That combustible materials now used be replaced wherever possible with non-flammable materials, that non-metallic materials that are used be arranged to maintain fire breaks, that systems for oxygen or liquid combustibles be made fire resistant, and that full flammability tests be conducted with a mockup of the new configuration.

That a more rapidly and more easily operated hatch be designed and installed.

That on-the-pad emergency procedures be revised to recognize the possibility of cabin fire.

The astronaut member of the Thompson Board assured NASA’s top officials that he would not have been afraid to enter the Grissom crew’s spacecraft that January day. Working with the board, however, Borman and everyone else had come to realize the substantial hazards that had been present but not recognized before the fire.

As its final report was being put together, the review board recognized that there had been ignorance, sloth, and carelessness, but the key word in, all the detailed information was “oversight.” No one, it seemed, realized the extent of fire hazards in an overpressurized oxygen-filled spacecraft cabin on the ground, according to the summary report the board issued on April:

Although the Board was not able to determine conclusively the specific initiator of the Apollo 204 fire, it has identified the conditions which led to the disaster–:

1.A sealed cabin, pressurized with an oxygen atmosphere.

2.An extensive distribution of combustible materials in the cabin.

3.Vulnerable wiring carrying spacecraft power.

4.Vulnerable plumbing carrying a combustible and corrosive coolant,

5.Inadequate provisions for the crew to escape,

6.Inadequate Provisions for rescue or medical assistance,

Having identified the conditions that led to the disaster, the Board addressed itself to the question of how these conditions came to exist. Careful consideration of this question leads the Board to the conclusion that in its devotion to the many difficult problems of space travel, the Apollo team failed to give adequate attention to certain mundane but equally vital questions of crew safety. The Board’s investigation revealed many deficiencies in design and engineering, manufacture and quality control.

The Thompson Board report came to almost 3000 pages; divided into 14 booklets, it made up a stack about 20 centimeters high. The six appendixes were: (A) the minutes of the board’s own proceedings; (B) eyewitness statements and releases; (C) the Operations Handbook for spacecraft 012; (D) final reports of all 21 panels;

(E) a brief summary of management and organization; and (F) a schedule of visible evidence.

But even before the board issued its report, its conclusions were essentially already public. For instance, a month after the fire Mueller had admitted to Congress that, after six safe years of manned flight experience, it was now obvious that NASA’s approach to fire prevention had been wrong. Minimizing the possibility of ignition had not been enough. Safeguards against the spreading of any fire must also be developed. Since it would be nearly impossible to design equipment that would protect the crews both on the ground and in space,* any nonmetallic, and perhaps flammable, materials would have to be carefully screened. In particular, the “four Fs”– fabrics, fasteners, film, and foams–required further investigation. Wiring, plumbing, and packaging must be reevaluated, even if it meant reviving the old debate about a one- versus two-gas environmental control system.”

As they delved deeper into the reasons behind the tragedy, NASA officials were confronted by some “skeletons in their closet.” Senator Walter F. Mondale raised the question of negligence on the part of management and the prime contractor by introducing the “Phillips report” of 1965-1966. The implication was that NASA had been thinking of replacing North American. But the charges were vague; and, for the next several weeks, no one seemed to know exactly what the Phillips report was. In fact, Webb at first denied that there was such a report. Mondale also alluded to a document (The Baron Report) by a North American employee, Thomas R. Baron, that was critical of the contractor’s operations at the Cape.

Baron was a rank and file inspector at Kennedy from September 1965 until November 1966, when he asked for and received a leave of absence. He had made observations; had collected gossip, rumor, and critical comments from his fellow employees; and had written a set of condemnatory notes. He had detailed, but not documented, difficulties with persons, parts, equipment, and procedures. Baron had observed the faults of a large-scale organization and apparently had performed his job as a quality inspector with a vengeance. He noted poor workmanship, spacecraft 012 contamination, discrepancies with installations, problems in the environmental control system, and many infractions of cleanliness and safety rules.

Baron passed on these and other criticisms to his superiors and friends; then he deliberately let his findings leak out to newsmen. North American considered his actions irresponsible and discharged him on 5 January 1967. The company then analyzed and refuted each of Baron’s charges and allegations. In the rebuttal, North American denied anything but partial validity to Baron’s wide-ranging accusations, although some company officials later testified before Congress that about half of the charges were well-grounded. When the tragedy occurred, Baron was apparently in the process of expanding his 55-page paper into a 500-page report.

When his indictments were finally aired before Teague’s subcommittee, during a meeting at the Cape on 21 April, Baron’s credibility was impaired by one of his alleged informants, a fellow North American employee named Mervin Holmburg. Holmburg denied knowing anything about the cause of the accident, although Baron had told the committee that Holmburg “knew exactly what caused the fire.” Holmburg testified that Baron “gets all his information from anonymous phone calls, people calling him and people dropping him a word here and there. That is what he tells me.” Ironically, Baron and all his family died in a car-train crash only a week after this exposure to congressional questioning.

Beyond the Phillips and Baron reports, however, recollections of events and warnings during the past six years made each Apollo manager wonder if he had really done all in his power to prevent the tragedy. It, March 1965, for instance, Shea and the crew systems people in Houston had wrestled with the question of the one–or two-gas atmosphere and the likelihood of fire– most of the studies were, admittedly, based on the possibility of fire in space–and concluded that a pure oxygen system was safer, less complicated, and lighter in weight. The best way to guard against fire was to keep flammable materials out of the cabin. Hilliard W. Paige of General Electric had, as a matter of fact, warned Shea about the likelihood of spacecraft fires us, the ground as recently as September 1966; and, just three weeks before the accident, Medical Director Charles Berry had complained that it was certainly harder to eliminate hazardous materials from the Apollo spacecraft than it had been in either Mercury or Gemini.

Although the Senate committee had begun its hearings while the board investigation was in progress, the House subcommittee waited until the final report was ready. By then, the Senate had touched on most of the major issues. As expected, the exact cause of the fire in spacecraft 012 was never determined, but the analysis of all possibilities led to specific corrective actions that eventually satisfied Congress. Throughout the hearings, Borman, still wearing two hats–as an astronaut and as a member of the Apollo 204 Review Board–was very effective. In the course of his testimony, Borman reiterated that the cause of the fire was oversight, rather than negligence or overconfidence. Fire in flight, he said, had been a matter of grave concern since the early days of aviation and the subject of numerous studies. But the notion that a fire hazard was increased on the ground by the use of flammable materials and an overpressure of pure oxygen had never been seriously considered.

On one occasion, when astronauts Walter Schirra, Slayton, Alan Shepard, and James McDivitt had expressed their confidence in NASA’s future safety measures, Borman answered a congressman’s doubts by saying:

You are asking us do we have confidence in the spacecraft, NASA management, our own training, and…our leaders. I am almost embarrassed because our answers appear to be a party line. Everything I said last week has been repeated by the people I see here today. The response we have given is the same because it is the truth…. We are trying to tell you that we are confident in our management, and in our engineering and in ourselves. I think the question is really: Are you confident in us?

When Borman made a plea on 17 April to stop the witch hunt and get on with Apollo, both NASA and North American had responded to the criticisms of the Thompson Board and of Congress. Top-level personnel changes were direct outgrowths of the charges of negligence and mismanagement: Everett E.

Christensen at NASA Headquarters resigned as Apollo mission director; George Low replaced Shea as Apollo Spacecraft Program Manager in Houston; and William D. Bergen (formerly of the Martin Company) took over from Harrison Storms as president of North American’s Space and Information Systems Division. Bergen brought with him two associates from Martin: Bastian Hello to run the Florida facility for North American and John P. Healy to manage the first manned Block II command module at Downey. Healey was expected to set precedents in guiding a nearly perfect spacecraft through, the factory.

Most North American officials weathered congressional criticism and pointed out that they agreed, in part, with the formal findings and recommendations of the Thompson Board.* But North American objected to the word “chronic” in describing problems with the environmental control system and defended its electrical wiring practices as functional rather than beautiful. Concurring that the fire probably started from an electrical spark somewhere near the environmental unit, the manufacturers also agreed with NASA on why the fire spread:

Not withstanding this emphasis on the potential problems created by combustibles in the spacecraft, it can be seen in retrospect that attention was principally directed to individual testing of the material. What was not fully understood by either North American or NASA was the importance of considering the fire potential of combustibles in a system of all materials taken together in the position which they would occupy in the spacecraft and in the environment of the spacecraft.

Leland Atwood and Dale Myers used charts to emphasize to Congress the changes that the company intended to make in both construction and test operations. North American would assign a spacecraft manager and a personalized team to each vehicle, appoint an assistant program manager whose only concern was safety, place additional controls on changes made during modification and checkout phases, and assign personal responsibility to specific inspectors. The company would also revise its fabrication and inspection criteria; expand its quality standards, issuing a handbook with better visual aids; install more protected wiring and plumbing; and insist upon additional major inspections. Myers then discussed fire-related hardware changes: the new unified hatch, materials reevaluation, fluids and plumbing reassessment, electrical system improvements, revised on-the-pad operations, and flammability tests.

In Houston, Faget’s engineering and development activity ran all sorts of tests on materials and components, and Robert Gilruth sent Borman with a Houston “tiger team” to Downey in mid-April.* The astronaut was to make on-the-spot decisions on contractual changes for the unified hatch, better wiring and plumbing techniques, and other improvements that had been planned even before the accident. Borman’s tiger team watched closely, lending its assistance when necessary, as North, Americas, engineers went over the spacecraft piece by piece.

What had happened to the command module, obviously, could just as well happen to the lunar module. Immediately after the fire, Thomas J. Kelly and a host of Grumman workers began a comprehensive review of materials in the lunar lander. Low sent Robert L. Johnston, a materials expert, to help Kelly’s group. Grumman replaced nylon cloth in the spacecraft, relying mostly on Beta fiber (an inorganic substance developed by the Corning Glass Works, that would not catch fire nor produce toxic fumes) Perhaps the most important application of this material was as “booties” around circuit breakers, to lessen the possibilities of electrical shorts. In other areas, Grumman worked on its forward hatch, to ensure a crew exit within 10 seconds; the environmental control system; and a cabin and ex- terior pressure equalization system. All in all, the changes would add a three– to four–month delay in deliveries to the schedule trouble the lauder was in even before the fire. Phillips sent a group headed by Roderick O. Middleton of Kennedy to look into Grummans quality control and inspection procedures.. Middleton’s audit team completed its report in mid-May, giving rumman generally good marks in the manufacturing process.

In Washington, on 9 May, Webb was again called on the carpet by the Senate committee. The Phillips report was again a major subject for debate, this time in a context that made it appear that the NASA–North American relationship was in danger of becoming a political football. The very next day, however, congressional questioning began to wind down. As Congressman John W. Wydler put it:

Essentially the story of the Apollo accident is known to the American people. We have admissions and statements about the things that NASA … and … North American Aviation [were] doing wrong. . . . . But I want to say this to you, Mr. Webb. Over the past few years….I probably have been one of the most critical

members on this committee of NASA. It appeared to me. . . . that you have had it too easy for your own good from this committee. This is not a criticism being directed at you or the Space Agency, but a criticism being directed inwardly at the Congress and this committee. I feel right now that you got less criticism than you deserved fin the past, but now] you are getting more criticism than you deserve. I don’t intend to add to it for that reason.

Wydler did not really stop there, of course, but the investigation did begin to fade away. NASA and North American began implementing the technical recommendations. To some degree, the accident actually bought time for some pieces of Apollo–the lunar module, the Saturn V, the guidance and navigation system, the computers, and the mission simulators–to catch up with and become adapted to the total configuration.”

Meanwhile, on 23 April 1967 the Soviet Union announced the launching of Vladimir M. Komarov aboard a new spacecraft. Soyuz I appeared to be functioning normally at first. On its second day of flight, however, the craft began to tumble, and Komarov had to use more attitude fuel than he wanted to get the ship under control. He tried to land during his 17th circuit but could not get the proper orientation for retrofire. Komarov succeeded in reentering on the 18th revolution, but his parachute shroud lines entangled. The cosmonaut was killed on impact. So both Soystz I and Apollo 1 put their programs through traumatic reassessments. No one found any consolation in a “rebalanced” space race. In fact, Webb took the occasion to emphasize the need for international cooperation by asking: “Could the lives already lost have been saved if we had known each other’s hopes, aspirations and plans? Or could they have been saved if full cooperation had been the order of the day?”

THE SLOW RECOVERY

Within days after the Thompson Board’s report, more than a thousand of those at the Manned Spacecraft Center who were working directly in support of the formal investigation began making suggestions for meeting the board’s recommendations. Materials selection, substitution, and stowage inside the command module were thoroughly restudied; and all cloth parts made of nylon were replaced by Beta fiber, teflon, or fiber glass. These substitutes were chosen after more than 3000 laboratory tests had been run on more than 500 different kinds of materials. (32)

Of immediate importance was the new unified hatch–unified meaning that the complicated two-hatch system was redesigned into a single hatch. The new component was heavier than the old, but it would open outward in five seconds, had a manual release for either internal or external operation, and would force the boost cover cap out of the way on opening. It could also be opened independently of internal overpressure and would be protected against accidental opening by a mechanism and seal similar to those used on Gemini.

The management of all industrial safety offices within NASA was revamped, with responsibilities flowing directly to the top at each location. At the launch center, fire and safety precautions were upgraded and personnel emergency preparations were emphasized as never before. Also, at the launch complex itself, a sliding wire was added to the service structure to permit a rapid descent to the ground. Reliability

and test procedures were more firmly controlled, making it difficult to inject any last minute or unnecessary changes.

At the Manned Spacecraft Center, full-scale flammability testing continued, first to try to duplicate the conditions present on 27 January and then to find ways to improve the cabin atmosphere and the environmental control system. The tests led to replacing all aluminum oxygen lines that had solder joints with stainless steel tubing that used brazed joints. Aluminum tubing solder joints that could not be eliminated from the coolant system were armored with sleeves and seals wherever exposed. NASA decided to keep the water-glycol coolant fluid (covering it with flame resistant outer insulation) and added emergency oxygen masks for protection from smoke and fumes. (33)

At NASA Headquarters, Webb directed Mueller to revamp and reorganize the major supporting and integrating contractors to put more pressure on North American, as well as on those manufacturing the other Apollo vehicles. Boeing was given a technical integration and evaluation contract, to act as a watch dog for NASA; and General Electric was told to assume a much greater role in systems analysis and ground support.

The contract situation with North Americas, had reached a peculiar stage even before the fire. The cost-plus.incentive.fee contract NASA had negotiated with North American in October 1965 had expired on 3 December 1966. In late January 1967, the legal status of relations was in some doubt. The objectives of the

incentive contract had been to reverse the trend of continuing schedule slips, to get Block I vehicles delivered from the factory, to speed up Block II manufacturing, and to bring costs under control. Progress had been made on all fronts by the end of 1966; the flights of Block I spacecraft 002, 009, and 011 had been 80 percent successful, Block II work had moved along, and the cost spiral had stopped.

Despite the fire, John J. McClintock, chief of the Apollo office program control division, advocated in April 1967 that NASA negotiate a follow-on incentive contract, placing heaviest emphasis on flight performance and quality and less on schedules. North American’s business negotiators had already conceded that no incentive fee could be expected for spacecraft 012. The closeout cost for the Block I series was set at $37.4 million. This meant that the learning phase of Apollo had cost $616 million. Furthermore, North American agreed that there would be no charge for changes resulting from the AS-204 accident–such as the wire harnesses, environmental control system improvements, and the unified hatch. Changes that would enhance mts5ion success or operational flexibility–changes in the reaction control system, revised inspection criteria, or features to increase mission longevity–would cost money.

After the uncertain days of February, NASA officials began to sense that a recovery from the tragedy was under way. Drawing together, workers at all NASA centers, representing a vast amount of technical, recovered their morale through hard work more rapidly than might have been expected. Much of Apollo’s chance for recovery rested on the fact that the Block II advanced version of the command module was

well along in-manufacturing and that most of its features were direct improvements over-the faults of the earth-orbital Block I. Moreover, the Saturn V, after experiencing difficulties in the development of its stages, seemed on the track now.

By early May, Webb and his top staff were looking for ways to show Congress that Apollo was on the road to recovery. Mueller proposed flying a Saturn V as soon as possible. Phillips stressed the building and delivery of standard vehicles. Any modifications of support missions other–than the lunar landing (such as Apollo Applications) should, he and Mueller agreed, be entirely separate from the mainstream of Apollo. Moreover, the science program in Apollo should be carried strictly as supercargo.

At the time of the accident, the flight schedule had listed a possible lunar landing before the end of 1968. After the impounding of material evidence and the halting of oxygen chamber testing until the investigation was over, that Apollo schedule was obviously no longer valid. Several weeks after the fire Seamans told blueller to scrap all official flight schedules for manned Apollo missions, using only at, internal working schedule to prevent avoidable slips and cost overruns. By March, Mueller had told Seamans that NASA could commit a Saturn V to a mission. In June Low said he believed that the spacecraft had turned the corner toward recovery, since the changes related to the fire had been identified and were being made. Even if everything went perfectly, however, more than 14 months would be needed for complete recovery.

To make certain of stronger program control in the future, Low decided that all proposals for changes would have to pass an exceedingly tough configuration control board before being adopted. He asked George W. S. Abbey, his technical assistant, to draft a strongly worded charter for the control board. Low next announced that he, Faget, Chris Kraft, Slayton, Kenneth Kleinknecht, William Lee, Thomas Markley, and Abbey (as secretary) would meet for several hours every Friday. When medical and scientific affairs were on the agenda, Berry and Wilmot N. Hess would join the group. Low himself would make all final decisions, and his new board members had the authority to ensure that his decisions were carried out.

If Apollo had seemed complicated before the fire, it appeared even more so afterward. If it gave an impression of being hurried in late 1966, it gathered still more momentum in late 1967. If an extreme level of attention had been given to aspects of crew safety and mission success before the deaths of Grissom and his crew, it rose yet higher after they were gone. But among the Apollo managers there were still nagging fears that something might slip past them, something might be impossible to solve. By mid-1967, however, they were so deep in their work that they could not avoid a growing confidence.

Atwood said the biggest mistake had been locking the crew inside the spacecraft and pumping in oxygen at a higher than sea-level pressure. There was no way to eliminate fire hazards under such conditions. So NASA and North American substituted a nitrogen-and-oxygen atmosphere at ground level, replacing the

nitrogen gradually with pure oxygen after launch. Bergen, who had taken over the leadership of North American’s Downey division from Storms, moved into the factory while recovery work was going on. He made a practice of appearing on the plant floor, walking around asking questions, during each of the three shifts. Some of the workers wondered if he ever slept. During visits to Downey, Low was often to be seen watching plant activities on Saturdays. Many doubted, Bergen later said, that the recovery could be made in a reasonable time because “everything had come to screeching halt.” Bergen credited Gilruth’s assignment of Borman and his group and Healey’s performance as manager of spacecraft 101 as the keys to getting the command module back into line.

NASA’s leaders, after reviewing the progress, decided that it was time for a flight demonstration to prove that the bits and pieces of Apollo had been picked up and were being put back together. Apollo-Saturn Mission 501, with command module 017, was set for early autumn of 1967. If the first flight of the Apollo–Saturn V combination was successful, the rest would follow in due course.

As early as 9 May 1967, Houston proposed four manned missions–one with only the command and service modules, the other three with all the vehicles–before any attempt at a lunar landing. Headquarters in Washington believed that the lunar-landing mission might be possible on the fourth manned flight, which Houston thought was unrealistic–“all-up” should not mean “all-out.” Kraft warned Low that a lunar landing should not be attempted “on the first flight which leaves the earth’s gravitational field”:

There is much to be gained from the operations which conducted on the way to and in the vicinity of the moon. The many questions of thermal control away from the earth’s environment, navigation and control during translunar flight, communications and tracking at lunar distances, lighting conditions and other flight experiences affecting astronaut activities in the vicinity of the moon, lunar orbit and rendezvous techniques, the capability of the MSFN to provide back-tip information and many other operating problems will be revealed when we fly in this new environment. It would be highly desirable to have had this experience when we are ready to commit to a lunar landing operation, thereby allowing a more reasonable concentration on the then new problems associated with the descent to the lunar surface.

Deputy Administrator Seamans and his aides made a swing around the manned space flight circuit in, June, visiting Kennedy, Huntsville, Mississippi Test, Michoud, and Houston. In the course of the tour, Seamans observed a definite upsurge of confidence within the Apollo team, although there were still worries. For example, at Kennedy, with planning predicated on a six-week checkout of the Apollo-Saturn in the Cape facilities and launch during the seventh week, there was some feeling that the schedule for the launch of Apollo 4* was extremely tight. Huntsville was still worried about the S-II stage of the launch vehicle, which had gone through, a rather tough year of testing in 1966. And Houston, as a result of fire-related changes, was fighting the age-old problem of fattening spacecraft. On top of this, the lunar module was still having ascent engine instability problems, also left over from the preceding year.

The next month, in July, Mueller and an entourage visited the North American plant at Downey* to see what the contractor had done about the Thompson Board’s recommendations. As they walked around the manufacturing area, Mueller seemed generally pleased with progress. (43) Within a very few months, that progress was to be demonstrated in a very satisfactory manner.

Apollo 4 and Saturn V

Birds, reptiles, and animals of higher and lower order that gathered at the Florida Wildlife Game Refuge (also known by the aliases of Merritt Island Launch Annex and Kennedy Space Center) at 7:00 in the morning of 9 November 1967 received a tremendous jolt. When the five engines in the first stage of the Saturn V ignited, there was a man-made earthquake and shockwave. As someone later remarked, the question was not whether the Saturn V had risen, but whether Florida had sunk.

Apollo-Saturn mission 501, now officially Apollo 4–the first all-up test of the three–stage Saturn V–was on its way. On its top rested spacecraft 017, a Block I model with many Block II features, such as an improved heatshield and a new hatch. The aim, of the mission, in addition to testing the structural integrity and compatibility of the spacecraft–launch vehicle combination, was to boost the command and service modules into an elliptical orbit and then power-drive the command module (in, an area over Hawaii) into the atmosphere as though it were returning from the moon to the earth. Apollo 4 also carrier a mockup of the lunar module. Weighing more than 2.7 million kilograms when fully fueled with Liquid oxygen and a kerosene mixture called RP-1, the Saturn, V first stage generated 7.5 million pounds of thrust at liftoff.

The flight went almost exactly as planned, and the huge booster rammed its payload into a parking orbit 185 kilometers above the earth. After two revolutions, the S-IVB third stage propelled the spacecraft outward to more than 17 000 kilometers, where it cut loose from the S-IVB and started falling earthward. Then the service module fired, to send the spacecraft out to 18 000 kilometers for a four-and-a-half hour soak in the supercold and hot radiation of space. Telemetry signals noted no degradation in cabin environment. with the spacecraft nose pointed toward the earth, the service module engine fired again. When the spacecraft reached the 122,000-meter atmospheric reentry zone, it was blunt-end forward and traveling at a speed of 40,000 kilometers per hour.

Seamen on the U.S.S. Bennington, the prime recovery ship in the Pacific, watched the descending spacecraft, with its parachutes in full bloom, until it landed 16 kilometers away about nine hours after its launch from Florida. Swimmers jumped from helicopters to assist in the recovery of spacecraft 017, which took about two hours. Technically, managerially, and psychologically, Apollo 4 was an important and successful mission, especially in view of the number of firsts it tackled. It was the first flight of the first and second stages of the Saturn V (the S-IVB stage had flown on the Saturn IB launch vehicles), the first launch of the complete Saturn V, the first restart of the S-IVB in orbital flight, the first liftoff from Complex 39, the first flight test of the Block II command module heatshield, the first flight of even a simulated lunar module, and so on. The fact that everything worked so well and with so little trouble gave NASA a confident feeling, as Phillips phrased it, that “Apollo (was] on the way to the moon.

Even before spacecraft 017 had set out on its trip, the Manned Spacecraft Center was working hard on how to get Apollo to the moon before 197O–only a little more than two years away. On 20 September, Low and others met with top manned space flight officials in Washington to present the center’s plan, the key features of which were the need for additional lander and Saturn V V development flights and the incorporation of a lunar orbital flight into the schedule. Owen Maynard presented plans for scheduling seven types of missions that would lead step by step to the ultimate goal. He described these steps, “A” through “G,” with G as the lunar landing mission.

Phillips asked that the group consider carefully both the pros and cons of flying an additional Saturn V flight. Wernher von Braun and Low favored the flight–von Braun, because he felt the launch operations people would need the experience, and Low, because he believed that data from several flights would be needed to make certain that the big booster was indeed ready for its flight to the moon. Against

these opinions, Phillips cited the tremendous workload an added flight would place on the preflight crews at Kennedy, and Mueller reminded the meeting of the already crowded launch – schedule for 1968. An additional lunar module mission would be flown only if LM-1 were unsuccessful.

Most discussion centered on the insertion of a lunar orbital flight into the schedule. Houston wanted “to evaluate the deep space environment and to develop procedures for the entire lunar landing mission short of LM descent, ascent and surface operations.” Mueller remarked that he regarded the lunar orbit mission as just as hazardous as the landing mission. But the Texas group argued that they had no intention of flying the vehicle closer to the moon than 15 000 meters. They pointed out that the crew would not have to train for the actual landing, but it would give them a chance to develop the procedures for getting into lunar orbit and undocking and for the rendezvous that the lunar landing crew would need. Mueller said, “Apollo should not go to the moon to develop procedures.” Low reminded him that crew operations would not be the main reason for the trip; there was still a lot to be learned about communications, navigation, and thermal control in the deep space environment. (46) Although a final decision on the lunar orbital mission was not made until later, Maynard’s seven-step plan was generally adopted throughout NASA.

Michael Robert Patterson was born in Arlington and is the son of a former officer of the US Army. So it was no wonder that sooner or later his interests drew him to American history and especially to American military history. Many of his articles can be found on renowned portals like the New York Times, Washingtonpost or Wikipedia.

Reviewed by: Michael Howard