U.S. Senate honors sinking of Thresher

3 April 2003

Forty years after the nuclear submarine U.S.S. Thresher sank to the bottom of the Atlantic Ocean, New Hampshire’s two senators supported legislation commemorating the event.

Senator John E. Sununu, R-N.H., introduced the bill Tuesday, and later that day it unanimously passed the Senate. Senator Judd Gregg, R-N.H. and Senators Olympia Snowe, R-Maine, and Susan Collins, R-Maine, were co-sponsors.

The submarine sank on April 10, 1963, about 220 miles east of Boston, as it conducted deep-diving exercises. All aboard — 16 officers, 96 enlisted men and 21 civilians — died in the tragedy.

“This legislation honors their brave service, and the service of all submariners who are ‘on eternal patrol,’” Sununu said in a press release. “The loss of the Thresher was an enormous tragedy for the U.S. submarine service, for the Navy and the nation.”

Gregg expressed similar feelings.

“The brave sailors and civilians aboard the U.S.S. Thresher made the ultimate sacrifice in support of our nation,” he said in a press release. “This measure we introduced recognizes the courage and bravery these men demonstrated in risking their lives in the development of the United States Navy’s submarine program, a program which has proven invaluable to the American military.”

The Thresher, built at Portsmouth Naval Shipyard in Maine, was commissioned in 1961 and underwent weapons tests, including on its torpedoes.

After the sub sank, the Navy investigated and determined that the most probable cause of the accident was a leak in its engine room because of corrosions in its pipes. This, in turn, could have caused electrical problems on the sub.

After the accident, the Navy established additional safety procedures, including the SUBSAFE program, which requires each submarine to pass a series of safety tests.

According to the press release, Sununu, Gregg and Maine’s two senators will introduce legislation asking Army Secretary Thomas E. White to create a memorial at Arlington National Cemetery honoring those who lost their lives on the Thresher as well as on all other nuclear subs that were lost at sea.

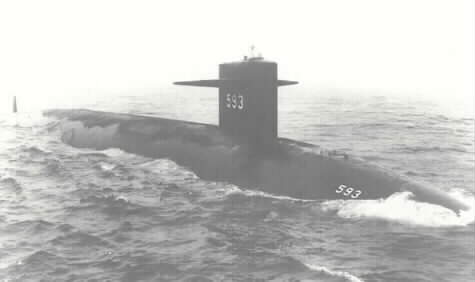

USS Thresher, lead ship of a class of 3700-ton nuclear-powered attack submarines, was built at the Portsmouth Naval Shipyard, Kittery, Maine. Commissioned in August 1961, she

conducted lengthy trials in the western Atlantic and Caribbean areas in 1961 and 1962, providing a thorough evaluation of her many new technological features and weapons. After the completion of these test operations, Thresher returned to her builders for overhaul.

On 10 April 1963, after the completion of this work, Thresher began post-overhaul trials. Accompanied by the submarine rescue ship Skylark (ASR-20), she transited to an area some 220 miles east of Cape Cod, Massachusetts, and started deep-diving tests. As these proceeded, garbled communications were received by Skylark, indicating trouble aboard the submarine. It gradually became apparent that she had sunk, taking the lives of 129 officers, crewmen and civilian technicians.

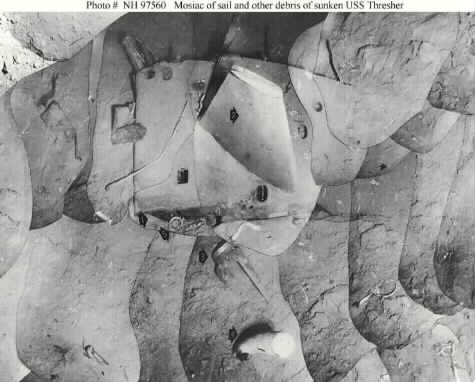

After an extensive underwater search utilizing the bathyscaph Trieste, oceanographic ship Mizar, and other ships, Thresher’s shattered remains were located on the sea floor, some 8400 feet below the surface. Deep sea photography, recovered artifacts and an evaluation of her design and operations permitted a Court of Inquiry to determine that she had probably sunk due to a piping failure, subsequent loss of power and inability to blow ballast tanks rapidly enough to avoid sinking. Over the next several years, a massive program was undertaken to correct design and construction problems on the Navy’s existing nuclear submarines, and on those under construction and in planning. Following completion of this “SubSafe” effort, the Navy has suffered no further losses of the kind that so tragically ended Thresher’s brief service career.

The Loss of the USS Thresher

Thirty-one years ago, the nuclear submarine USS Thresher failed to surface from a test dive and was lost at sea.

On the morning of April 10, the Thresher proceeded to conduct sea trials about 200 miles off the coast of Cape Cod. At 9:13 a.m., the USS Skylark received a signal indicating that the submarine was experiencing “minor difficulties.” Shortly afterward, the Skylark received a series of garbled, undecipherable message fragments from the Thresher. At 9:18 a.m., the Skylark’s sonar picked up the sounds of the submarine breaking apart. All hands were lost–129 lives.

The Investigation

The subsequent investigation of the disaster by the Navy identified a leak in an engine room seawater system as the most probable cause of the tragedy. Further, both the Navy’s investigation and a Congressional inquiry identified several additional probable causes linked to management, communication, and the practices and procedures employed by the Navy and the shipyards. These findings suggest a number of lessons applicable to the Department of Energy.

The Thresher was the first of a new class of nuclear submarine designed to dive significantly deeper than its predecessors. After nearly a year of record-breaking operations, the submarine underwent a scheduled shipyard overhaul that entailed significant alterations to its hydraulic power plant. Because of Fleet operational requirements and competition for resources with four other submarines under construction in the same shipyard, the overhaul was conducted under tight schedule constraints.

The Navy’s investigation concluded that while the Thresher was operating at test depth, a leak had developed at a silver-brazed joint in an engine room seawater system, and water from the leak may have short-circuited electrical equipment, causing a reactor shutdown and leaving the submarine without primary and secondary propulsion systems. The submarine was unable to blow its main ballast tanks, and because of the boat’s weight and depth, the power available from the emergency propulsion motor was insufficient to propel the submarine to the surface.

Practices and Procedures

After the investigation, the Navy embarked on an extensive review of practices and procedures in effect during the Thresher’s overhaul. The reviewers determined that existing standards at the time were not followed throughout the re-fit to ensure safe operation of the submarine. Four issues were of particular concern:

Design and Construction. The submarine was designed and built to meet two sets of standards. Because the submarine’s nuclear power plant was the focus of the engineers, the standards used for the nuclear power plant were more stringent than those for the rest of the submarine. As a result of the emphasis placed on nuclear-related aspects of the design, builders assigned less importance to the steam and saltwater systems, even though those systems were crucial to the operation and safety of the vessel.

Brazing. Two standards for silver-brazing pipe joints were used during the Thresher’s construction and overhaul. Brazing is a process that joins metal parts by heating them to a temperature sufficient to melt a filler material, which then flows into the space between the closely fitted parts by capillary action. Induction heating, which provides better joint integrity, was used for easily accessible joints. Where accessibility was restricted, hand-held torches were used. Reviewers determined that hand-held torches were used to heat many of the Thresher’s crucial, but less accessible, pipe joints.

Quality Assurance. A newly accepted nondestructive testing technology for quality assurance was not implemented for the Thresher’s overhaul. The Navy had experienced a series of failures with silver-brazing, which resulted in several near misses, indicating that the traditional quality assurance method, hydrostatic testing, was inadequate. Therefore, the Navy directed the shipyard to use ultrasonic testing, a method newly accepted by industry, on the Thresher’s silver-brazed joints. However, the Navy failed to specify the extent of the testing required and did not confirm that the testing program was properly implemented. When ultrasonic testing proved burdensome and time consuming, and when the pressures of the schedule became significant, the shipyard discontinued its use in favor of the traditional method. This action was taken despite the fact that 20 of 145 joints passing hydrostatic testing failed to meet minimum bonding specifications when subjected to ultrasonic testing.

Procurement. Finally, specifications for Government procurement were not strictly enforced. The Navy found that the reducing valve components installed in the pressurized air systems used to blow the main ballast tanks of the submarine did not meet design specifications. Because of the magnitude of the pressures anticipated, the valve manufacturer had added a strainer feature upstream of the reducing valves to protect the sensitive valves from particulate matter. When the Navy conducted tests on another Thresher-class vessel, it found that the pressure drop across the component at high flow rates caused entrained moisture to accumulate on the strainers and form enough ice to block the air flow. Venturi cooling, as this phenomenon is called, was thought to be the reason that the Thresher’s attempts to blow its main ballast tanks were ineffective.

Lessons Learned

The lessons learned by the Navy are still applicable and should be applied by the Department of Energy.

(1) Engineering, design, and construction must place equal weight on nuclear and nonnuclear systems when the operation of either system can affect the safety or integrity of an overall system.

(2) In selecting the standard for which a task is performed, the pressures of time and resources should not override the safe and continued performance of the result. Selecting the easy standard to save time and money increased the probability of a failed weld.

(3) Communication of near-miss events by management to various departments, or feedback, helps to resolve weaknesses or flaws that in future events could prove tragic.

(4) Procurement of equipment and components must be checked upon receipt as well as tested under operating conditions to verify its suitability. Valves or other parts could be assembled with counterfeit bolts, which will fail when stressed.

107th CONGRESS

1st Session

S. CON. RES. 46

Honoring the 129 sailors and civilians lost aboard the U.S.S. Thresher on April 10, 1963, and urging the Secretary of the Army to erect a memorial to this tragedy in Arlington National Cemetery.

IN THE SENATE OF THE UNITED STATES

June 5, 2001

Mr. GREGG (for himself, Mr. SMITH of New Hampshire, Ms. COLLINS, and Ms. SNOWE) submitted the following concurrent resolution; which was referred to the Committee on Veterans’ Affairs

CONCURRENT RESOLUTION

Honoring the 129 sailors and civilians lost aboard the U.S.S. Thresher on April 10, 1963, and urging the Secretary of the Army to erect a memorial to this tragedy in Arlington National Cemetery.

Whereas the U.S.S. Thresher was first launched at Portsmouth Naval Shipyard on July 9, 1960;

Whereas the U.S.S. Thresher departed Portsmouth Naval Shipyard for her final voyage on April 9, 1963, with a crew of 16 officers, 96 sailors, and 21 civilians;

Whereas the mix of that crew reflects the unity of military and civilian personnel in the naval submarine service, and in the protection of the Nation;

Whereas at approximately 7:47 a.m. on April 10, 1963, while in communication with the surface ship U.S.S. Skylark, and approximately 300 miles off the coast of New England, the U.S.S. Thresher began her final descent;

Whereas the U.S.S. Thresher was declared lost with all hands on April 10, 1963; and

Whereas the crew of the U.S.S. Thresher demonstrated the `last full measure of devotion’ in service to this Nation, and this devotion characterizes the sacrifices of all submariners, past and present:

Now, therefore, be it

Resolved by the Senate (the House of Representatives concurring), That the Congress–

(1) remembers with profound sorrow the loss of the U.S.S. Thresher and her gallant crew of sailors and civilians on April 10, 1963; and

(2) urges the Secretary of the Army to erect a memorial in Arlington National Cemetery to the crew of the U.S.S. Thresher, and to all United States submariners who have lost their lives in the line of duty.

Personnel Who Perished in the Loss of Thresher on 10 April 1963

Ship’s Company

- Arsenault, Tilmon J., ENCA (SS)-P2, USN.

- Babcock, Ronald C., LTJG, USN.

- Bain, Ronald E., EN2 (SS)-P2, USN.

- Bell, John E., MMI-P2, USN.

- Bobbitt, Edgar S., EM2 (SS)-P2, USN.

- Boster, Gerald C., EM3 (SS)-P1, USN.

- Bracey, George (n), 5D3 (SS), USN.

- Brann, Richard P., EN2 (SS)-P2, USN.

- Carkoski, Richard 3., EN2 (SS), USN.

- Carmody, Patrick W., 5K2, USN.

- Cayey, Steven G., TM2 (SS), USN.

- Christiansen, Edward (n), SN (SS), USN.

- Claussen, Larry W., EM2 (SS)-P2, USN.

- Clements, Thomas E., ETR3 (SS), USN.

- Collier, Merrill F., LT, USN.

- Cummings, Francis M., SOS2 (SS), USN.

- Dabruzzi, Samuel J., ETN2 (SS), USN.

- Davison, Clyde E., III, ETR3-P1, USN.

- Day, Donald C., EN3 (SS), USN.

- Denny, Roy O., Jr., EM1 (SS)-P2, USN.

- Di Nola, Michael 3., LCDR, USN.

- DiBella, Peter J., SN, USN.

- Dundas, Don R., ETN2 (SS), USN.

- Dyer, Troy E., ET1 (SS)-P1, USN.

- Forni, Ellwood H., SOCA (SS)-P1, USN.

- Foti, Raymond P., ET1 (SS), USN.

- Freeman, Larry W., FTM2 (SS), USN.

- Fusco, Gregory J., EM2 (SS)-P2, USN.

- Gallant, Andrew J., Jr., HMC (SS), USN.

- Garcia, Napoleon T., SD1 (SS), USN.

- Garner, John E., YNSN (SS), USN.

- Garner, Pat M., LCDR, USN.

- Gaynor, Robert W., EN2 (SS), USN.

- Gosnell, Robert H., SA (SS), USNR.

- Grafton, John G., LTJG, USN.

- Graham, William E., SOC (SS)-Pl, USN.

- Gunter, Aaron J., QM1 (SS), USN.

- Hall, Richard C., ETR2 (SS)-P2, USN.

- Harvey, John W., LCDR, USN. (Commanding Officer of Thresher)

- Hayes, Norman T., EM1-P1, USN.

- Heiser, Laird G., MM1-P2, USN.

- Helsius, Marvin T., MM2, USN.

- Henry, James J., Jr., LTJG, USN.

- Hewitt, Leonard H., EMCA (SS), USN.

- Hoague Joseph H., TM2 (SS), USN.

- Hodge, James P., EM2, USN.

- Hudson. John F., EN2 (SS), USN.

- Inglis, John P., FN, USNR.

- Johnson Edward A., ENCA (SS), USN.

- Johnson, Richard L., RMSA, USN.

- Johnson, Robert E., TMC (SS)-P1, USN.

- Johnson, Thomas B., ET1 (SS)-P2, USN.

- Johnson. Brawner G., FTG1 (SS)-P2, USN.

- Jones, Richard W., EM2 (SS), USN.

- Kaluza, Edmund J., Jr., SOS2 (SS)-P1, USN.

- Kantz, Thomas C., ETR2 (SS), USN.

- Kearney, Robert D., MM3, USN.

- Keiler, Ronald D., IC2 (SS)-P2, USN.

- Kiesecker, George J., MM2 (SS)-P2, USN.

- Klier, Billy M., EN1 (SS) P2, USN.

- Kroner, George R., CS3, USN.

- Lanouette, Norman G., QM1 (SS), USN.

- Lavoie, Wayne W., YN1 (SS), USN.

- Lyman, John S., Jr., LCDR, USN.

- Mabry, Templeman N., Jr., EN2 (SS)-P2, USN.

- Malinski, Frank J., LTJG, USN.

- Mann, Richard H., Jr., IC2 (SS), USN.

- Marullo, Julius F., Jr., QM1 (SS), USN.

- McClelland, Douglas R., EM2 (SS), USN.

- McCord, Donald J., MM1 (SS)-P2 USN.

- McDonough, Karl P., TM3 (SS), USN.

- Middleton, Sidney L., MM1 (SS)-P2, USN.

- Muise, Ronald A., CS2, USN.

- Musselwliite, James A., ETN2 (SS)-P2, USN.

- Nault, Donald E., CS1 (SS), USN.

- Noonis, Walter J., RMC (SS), USN.

- Norris, John D., ET1 (SS)-P2, USN.

- Oetting. Chesley C., EM2-P2, USN.

- Parsons, Guy C., Jr., LTJG, USN.

- Pennington, Roscoe C., EMCA (SS)-P2, USN.

- Peters, James G., EMCS-P2. USN.

- Phillippi. James F., SOS2 (SS), USN.

- Philput. Dan A., EN2 (SS)-P2, USN.

- Podwell, Richard (n), MM2-P2, USN.

- Regan, John S., MM1 (SS)-P2, USN.

- Ritchie, James P., RM2, USN.

- Robison, Pervis (n), Jr., SN, USN.

- Rountree, Glenn A., QM2 (SS), USN.

- Rushetski, Anthony A., ETN2, USN.

- Schiewe, James M., EM1 (SS)-P2, USN.

- Shafer, Benjamin N., EMCM (SS)-P2, USN.

- Shafer, John D., EMCS (SS)-P2, USN.

- Shimko, Joseph T., MM1-P2, USN.

- Shotwell, Burnett M., ETRSN, USN.

- Sinnett. Alan D., FTG2 (SS),USN.

- Smarz, John (n), Jr., LT, USN.

- Smith, William H., Jr., BT1-P2, USN.

- Snider, James L., MM1, USN.

- Solomon, Ronald H., EM1-P2, USN.

- Steinel, Robert E., SO1 (SS)-P1, USN.

- Van Pelt, Rodger E., IC1 (SS)-P2, USN.

- Walski, Joseph A., RMl (55)-P1, USN.

- Wasel, David A., RMSN, USN.

- Wiggins, Charles L., FTG1-P2, USN.

- Wiley, John J., LTJG, USN.

- Wise, Donald E., MMCA (SS)-P2, USN.

- Wolfe, Ronald E., QMSN (SS),USN.

- Zweifel, Jay H., EM2-P1, USN.

Personnel Other Than Ship’s Company

- Abrams, Fred P., Civilian Employee, Production Department, Portsmouth Naval Shipyard.

- Allen, Philip H., LCDR, USN, Portsmouth Naval Shipyard.

- Beal, Daniel W., Jr., Civilian Employee, Combat Systems Division, Portsmouth Naval Shipyard.

- Biederman, Robert D., LT, USN, Portsmouth Naval Shipyard.

- Billings, John H., LCDR, USN, Portsmouth Naval Shipyard.

- Charron, Robert E., Civilian Employee, Design Division, Portsmouth Naval Shipyard.

- Corcoran, Kenneth R., Contractor’s Representative, Sperry Corp.

- Critchley, Kenneth J., Civilian Employee, Production Department, Portsmouth Naval Shipyard.

- Currier, Paul C., Civilian Employee, Production Department, Portsmouth Naval Shipyard.

- Des Jardins, Richard R., Civilian Employee, Combat Systems Division, Portsmouth Naval

- Dineen, George J., Civilian Employee, Production Department, Portsmouth Naval Shipyard.

- Fisher, Richard K., Civilian Employee, Design Division, Portsmouth Naval Shipyard.

- Guerette, Paul A., Civilian Employee, Design Division, Portsmouth Naval Shipyard.

- Jaquay, Maurice F., Contractor’s Representative, Raytheon Corp.

- Keuster, Donald W., Naval Ordnance Laboratory

- Krag, Robert L., LCDR, USN, Staff, Deputy Commander, Submarine Force, U.S. Atlantic Fleet.

- Moreau, Henry C., Civilian Employee, Production Department, Portsmouth Naval Shipyard.

- Palmer, Franklin J., Civilian Employee, Production Department, Portsmouth Naval Shipyard.

- Prescott, Robert D., Civilian Employee, Design Division, Portsmouth Naval Shipyard Shipyard.

- Stadtmuller, Donald T., Contractor’s Representative, Sperry Corp.

- Whitten, Laurence E., Civilian Employee, Combat Systems Division, Portsmouth Naval Shipyard.

Michael Robert Patterson was born in Arlington and is the son of a former officer of the US Army. So it was no wonder that sooner or later his interests drew him to American history and especially to American military history. Many of his articles can be found on renowned portals like the New York Times, Washingtonpost or Wikipedia.

Reviewed by: Michael Howard